1.1 Paste Chemistry & Alloy Choice

Solder paste is the nervoussingle largest variable in the SMT process, responsible for over 65% of end-of-line defects. It is not merely "glue"; it is a complex rheological system that must withstand printing shear forces, hold components during transport, and chemically react to form a metallurgical bond during reflow. Selecting the wrong chemistry guarantees unstable printing, voiding, or latent field failures, regardless of Surfacehow Mountexpensive Technologyyour (SMT).printer Itsor chemicaloven mixis. Treat paste selection as an engineering specification, not a consumable commodity.

Flux System Selection: The Cleanliness Trade-Off

The flux vehicle dictates everythe stepprocess window, voiding performance, and residue risks. Choose the flux system based on the cleaning capability and reliability requirements of the linefinal —assembly.

Scenario howA: High-Reliability, Dense Assembly (Aerospace, Medical, High-Density Digital)

Requirement: Zero residue risk, maximum wetting on oxidized pads.

Action: Select Water-Soluble (WS) paste.

- Why: WS fluxes contain aggressive activators (organic acids) that clean

youroxidesstencilsrapidly.stayThey provide the widest wetting window and lowest voiding rates. - The Engineering Risk: The residue is corrosive. If the washing process fails (water temperature, pressure, or saponifier concentration drop), the remaining ionic contamination will cause dendritic growth and shorts.

- Mandatory Control: You must have an in-line cleaner and perform daily Ionic Contamination testing (ROSE/SEC) to

howverifyreliablecleaningyourefficacy.

Scenario areB: yearsStandard downIndustrial/Consumer (IoT, Control Boards, LED)

Requirement: Cost efficiency, no cleaning process.

Action: Select No-Clean (NC) paste (ROL0/ROL1).

- Why: The residue is engineered to be non-conductive and benign after reflow. It eliminates the

road.capitalTheandbalanceoperating expense of a wash line. alloyThe Engineering Risk:,"No-Clean" does not mean "Invisible."fluxIf Reflow is too Cold:,Activators remain unreacted and conductive -> Leakage currents.powderIfsizeReflow is too Hot:definesResidueyourcharsentire->processInterfereswindow.withGetIn-CircuitthisTestright,(ICT)andprobesproduction(falsehums;failures).

- Mandatory

getControl:itVerifywrong,fluxandcompatibilityyou’llwithbeconformalchasingcoatingyieldifproblemsused.forever.Validate ICT probeability.

What’sAlloy inSelection: aThermal Solder& Paste?Mechanical (The Three Knobs)Integrity

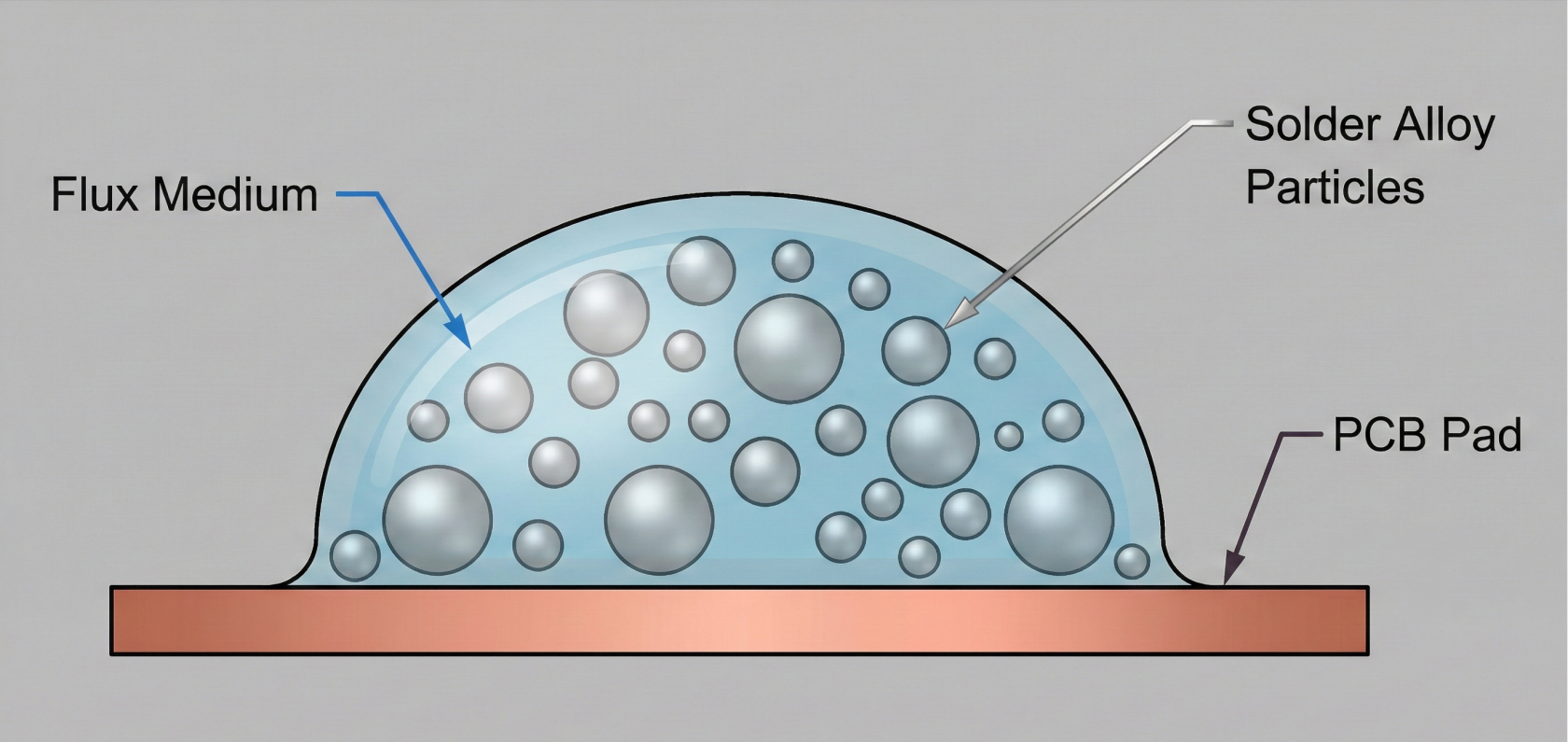

EveryThe pastealloy is a suspension of three things, and you control all three:

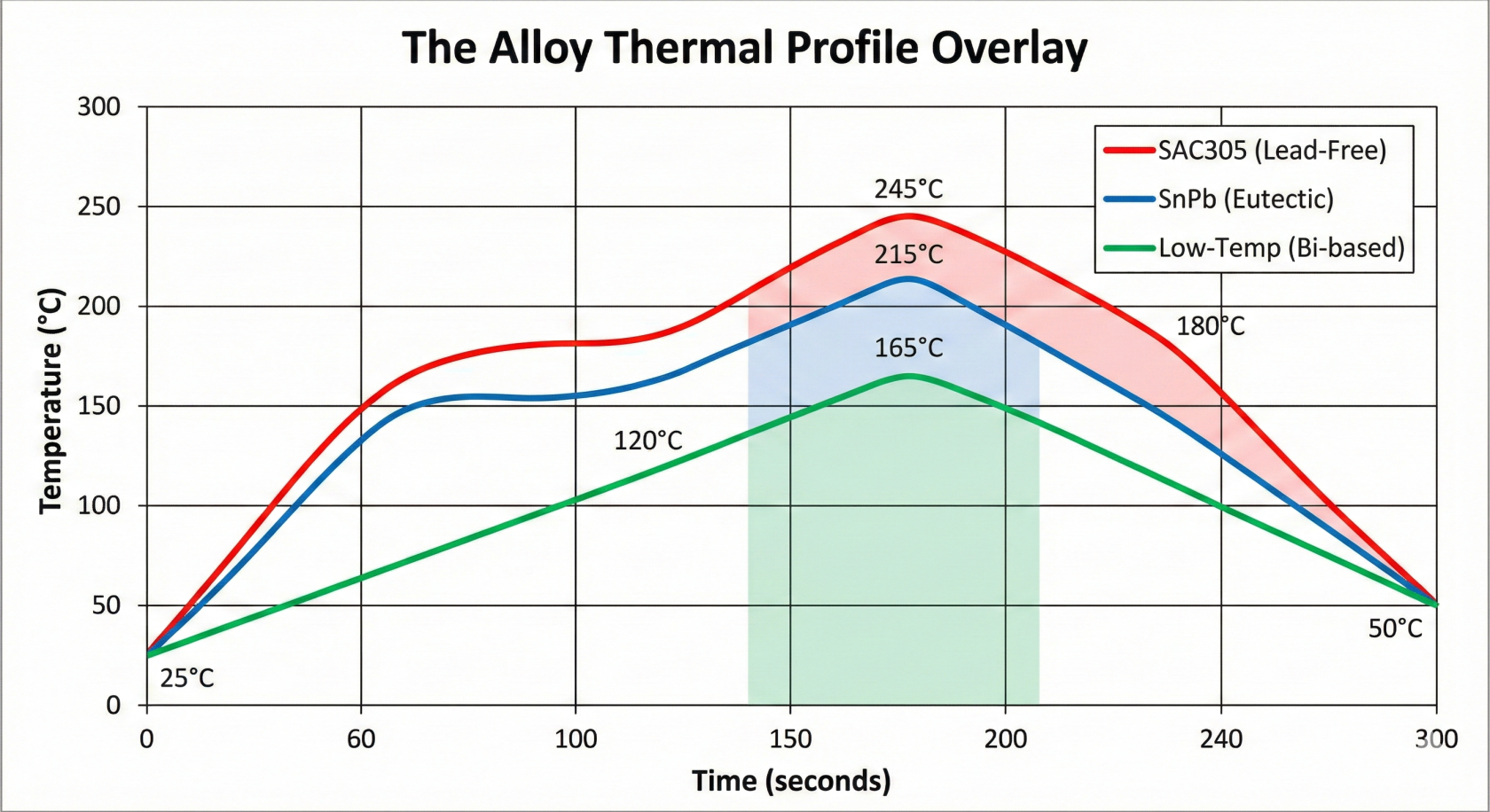

Alloy:Setsdefines the melting point(thermal profile)and thelong-termmechanicalstrength/reliabilityfatigue resistance of the joint. Do not default to "Standard SAC305" without verifying the application constraints.Standard Application: SAC305 (Sn96.5 / Ag3.0 / Cu0.5)

- Melting Point: ≈ 217˚C – 220˚C.

Flux:Usage: Theengineindustryroom.defaultItforcleansgeneral SMT.- Outcome: Provides acceptable thermal cycling performance for consumer electronics (0˚C to 60˚C operational range).

- Limit: Avoid for high-stress automotive or aerospace applications where thermal shock exceeds -40˚C to +125˚C.

High-Reliability Application: Doped Alloys (SAC-Q, SAC-I, SnNi)

- Usage: Automotive under-hood, ruggedized industrial.

- Mechanism: Dopants like Bismuth (Bi), Nickel (Ni), or Antimony (Sb) pin the

metal,grainpreventsboundariesoxidationof the solder structure. - Outcome: Prevents micro-cracks propagation during

heating,thermaldictatescycling.stencilmeasurablelife,2x – 3x increase in drop-shock anddeterminesthermal fatigue life compared to standard SAC305.

Low-Temperature Application: SnBi (Tin-Bismuth)

- Melting Point: ≈ 138˚C.

- Usage: Heat-sensitive components (cheap LEDs, PET flex circuits).

- Risk: The joint is brittle.

- Engineering Consequence: Mechanical shear strength is < 50% of SAC305. Boards must not be subjected to drop shock or bending. Never mix SnBi paste with SAC305 component balls unless specifically profiled to fully mix the alloy, or the joint will fail catastrophically.

Pro-Tip: If your Voiding Rate on QFN thermal pads exceeds 25% (IPC Class 3 failure), do not just tweak the profile. Switch to a "Low-Voiding" flux formulation specifically engineered with different solvent outgassing rates. Chemistry fixes voiding better than profiling does.

cleaningrequirements.Powder Size (

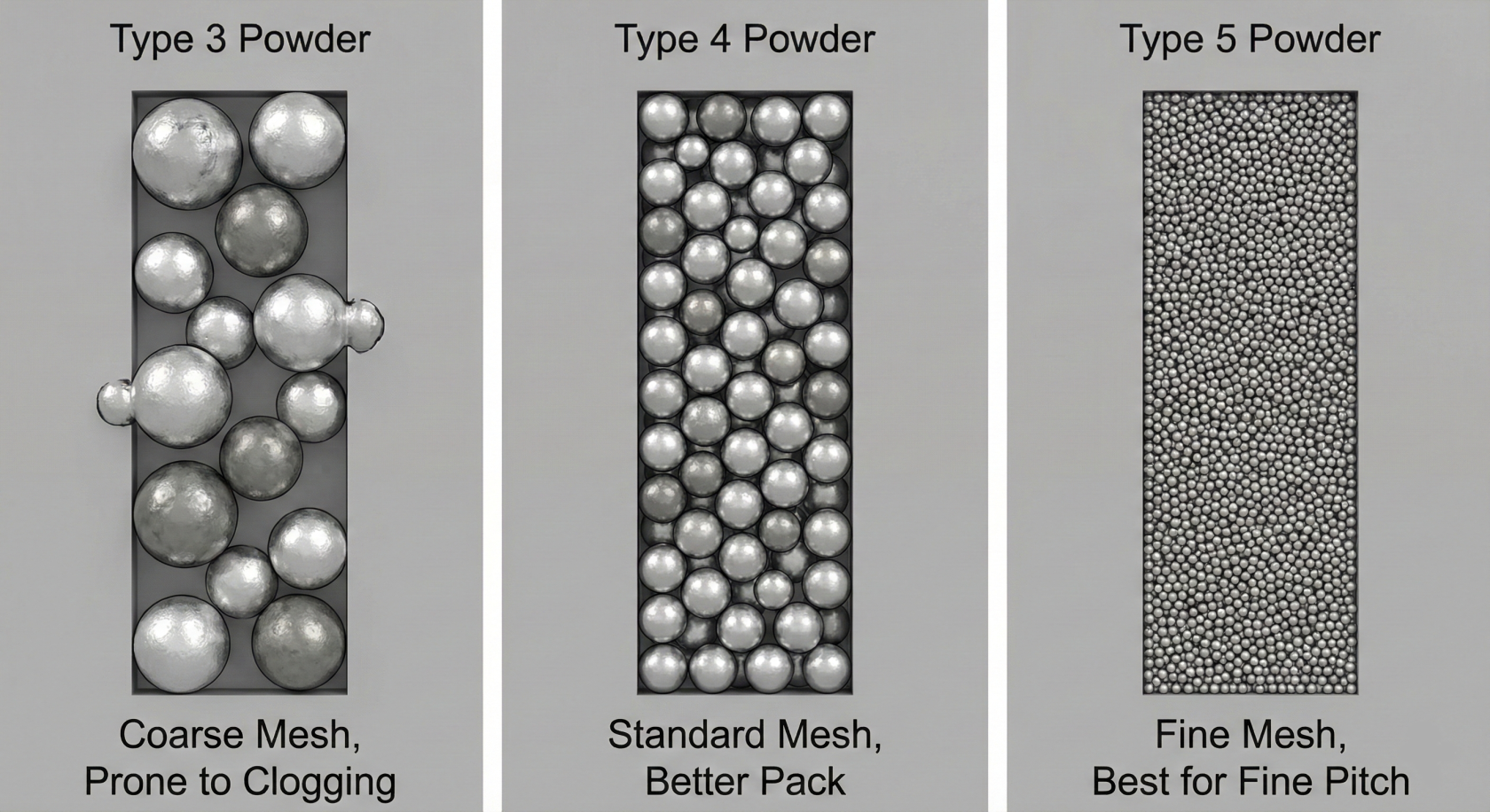

Type):Mesh) & Release StabilityParticle size controls the release of paste from the stencil aperture. Mismatched powder size leads to clogging, insufficiency, and rapid oxidation.

Logic for Powder Selection:

- If

UnlocksSmallest Pitch ≥ 0.5 mm AND Smallest Aperture Width > 0.25 mm:- Use Type 3 (T3) (25 – 45 µm).

- Benefit: Lower surface area oxide, longer stencil life (> 8 hours), lower cost.

- If Smallest Pitch 0.4 mm OR Area Ratio (AR) is 0.60 – 0.66:

- Use Type 4 (T4) (20 – 38 µm).

- Reason: T3 particles will block the aperture. T4 is the modern standard for mixed-technology boards.

- If Smallest Pitch ≤ 0.3 mm (01005s, µBGA):

- Use Type 5 (T5) (15 – 25 µm).

- Risk: High surface area leads to rapid flux exhaustion.

- Consequence: Stencil life is reduced to < 4 hours. You must replenish paste more frequently to maintain tack and flux activity.

Pro-Tip: Never top up a jar of T4 paste with leftover T3. The mixed rheology will cause unpredictable rolling and release, destroying your

abilityCp/Cpk.Traceability & Incoming Control

You cannot control the process if you do not control the material. Every jar of paste must be tracked.

- Lot Number: Record and link to

print fine features. It’sthegatekeeperProductionforJobareaID.ratioandvolume consistencyon small pads.

- If

Flux Systems: No-Clean vs. Water-Soluble

This is the firstonly majorway decision,to impacting cost, cycle time, and risk.

|

|

|

|

|

|

|

|

|

|

|

|

Pro Tip:Action: If youDOM have> wetting6 issuesmonths or-> excessiveDispose. voidsDo onnot BGAs,requalify. WSThe flux activators degrade over time even in cold storage.

- Drift: If metal load is too low (high flux content), slump and bridging increase. If too high, paste

isdriesthe technical solution. But remember, you’re trading a printing problem for a costlyout andcomplexclogs.cleaning processyou must now validate and control 24/7.

PowderFinal Size: Matching Aperture RatiosChecklist

The powder type must be smaller than the smallest stencil aperture opening to avoid clogging. This is where your Design for Manufacturing (DFM) meets reality.

|

|

|

|

|

|

|

|

|

|

|

|

Fast Rule: If your minimum Area Ratio (Aperture Area / Aperture Wall Area) drops below 0.66, you must upgrade to the next smaller powder type (e.g., T3 – T4 – T5) to ensure consistent volume release and minimize clogging. Tighter powder means tighter storage, handling, and print control.

Alloy Choice: Performance, Profile, and Reliability

Alloy choice sets the thermal profile and, more importantly, the long-term joint integrity.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Manager Takeaway: For high-reliability, cycling applications, explore doped SAC alloys (e.g., SAC-Q, SAC-I). These specialty pastes are engineered to resist micro-cracking and improve service life where temperature extremes are a factor.

Mapping Your Paste to Your Process Window

The final choice must satisfy three critical axes simultaneously:

Print Axis (Rheology & Powder):Does the paste’srheology(its internal viscosity/flow) allow it to hold shape perfectly after the print stroke, or does itslumpand cause bridging? Is thetackstrong enough to hold small 0201/0402 components through conveyor travel before reflow?(Check this with SPI/AOI data.)Reflow Axis (Alloy & Flux):Do the chosen alloy and flux chemistry allow you to consistently hit your targetTALandPeak Temperaturewithout oxidizing the flux or stressing the components?(Check this with thermal profiling.)Cleanliness Axis (Risk & Process):If you choose water-soluble, is thewash process controlled and verifiedto IPC standards? If you choose no-clean, do you havezero field failuresrelated to residue, and are your test probes happy?(Check this with ionic testing and test yield data.)

When the window feels tight, resist the urge to change the operator's settings. Change the paste, the stencil, or the atmosphere (add N2) instead. Run a small Design of Experiments (DOE) to find the sweet spot, then lock it down.

Final Checklist: Paste Selection Requirements

The paste selection must be verified against all process and reliability requirements before purchase.

|

|

|

Flux |

|

|

Halogen Content | Halogen-Free vs. Halogenated | Confirm customer environmental compliance ( |

Alloy | Specific | Confirm reflow oven capability (Max temp vs. component limits). |

Powder Size | Type |

|

|

|

|

|

|

|

|

|

|