1.1 Paste Chemistry & Alloy Choice

Solder paste sits at the heart of surface mount assembly, and its chemistry quietly dictates how smooth—or how painful—production will be. The balance of flux, powder size, and alloy determines everything from stencil performance to reflow stability and long-term reliability. Every tradeoff—between print life and fine-pitch resolution, between wetting power and cleaning demands, between thermal limits and mechanical strength—defines the process window that keeps yields high and surprises low. Choosing wisely here sets the tone for the entire manufacturing line.

1.1.1 What’s in a solder paste (and why you should care)

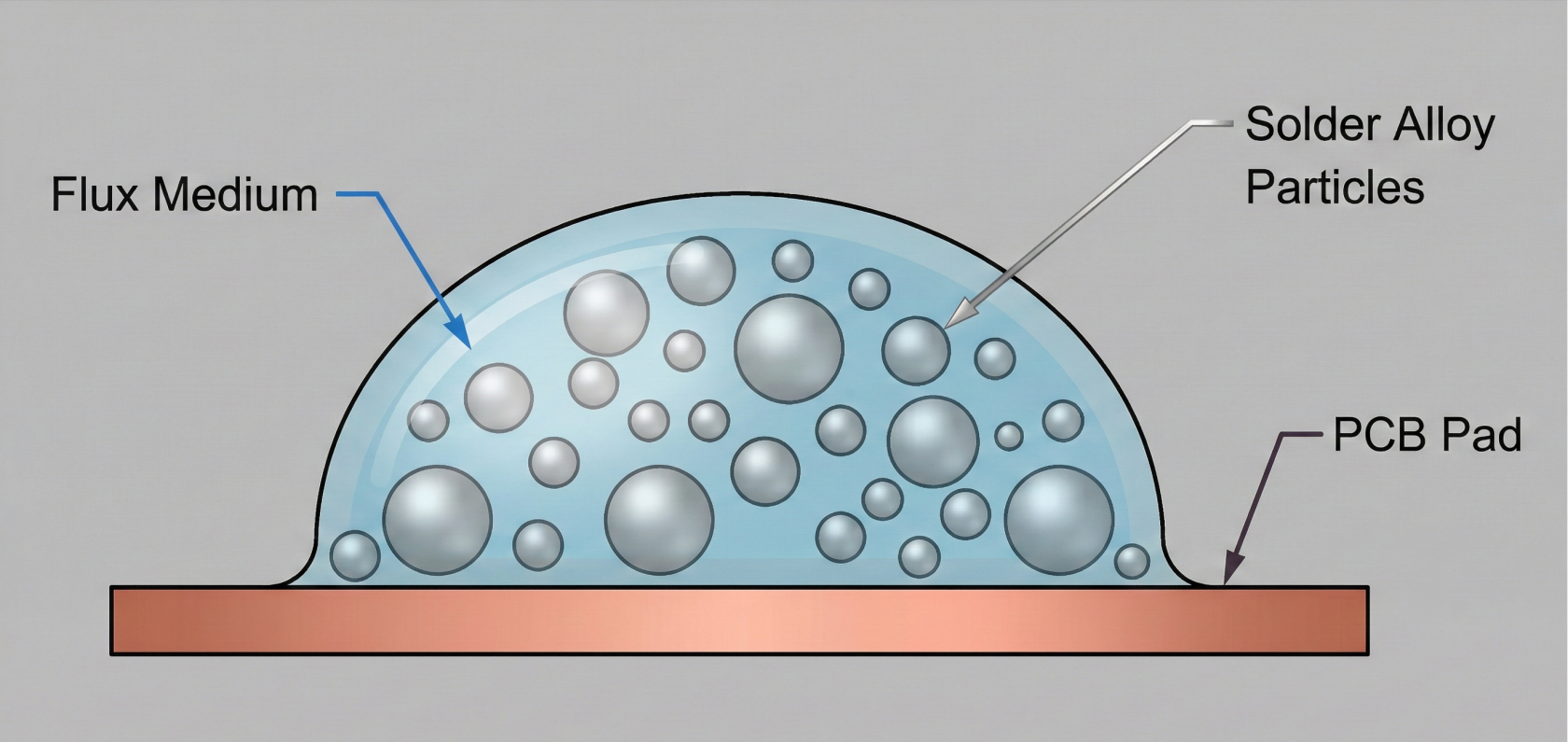

A paste is alloy + flux + powder size. Alloy sets melting temp and long-term behavior; flux decides print life, wetting, residue/cleaning; powder size unlocks your fine apertures without slumping or clogging. Every knob you twist here shows up in printing and reflow later—so pick on purpose.

1.1.2 Flux systems (no-clean vs water-soluble)

If in doubt, start no-clean, prove residues are acceptable, and keep water-soluble in your back pocket for stubborn wetting/voiding cases.

1.1.3 Powder size (why Type 3/4/5 isn’t just marketing)

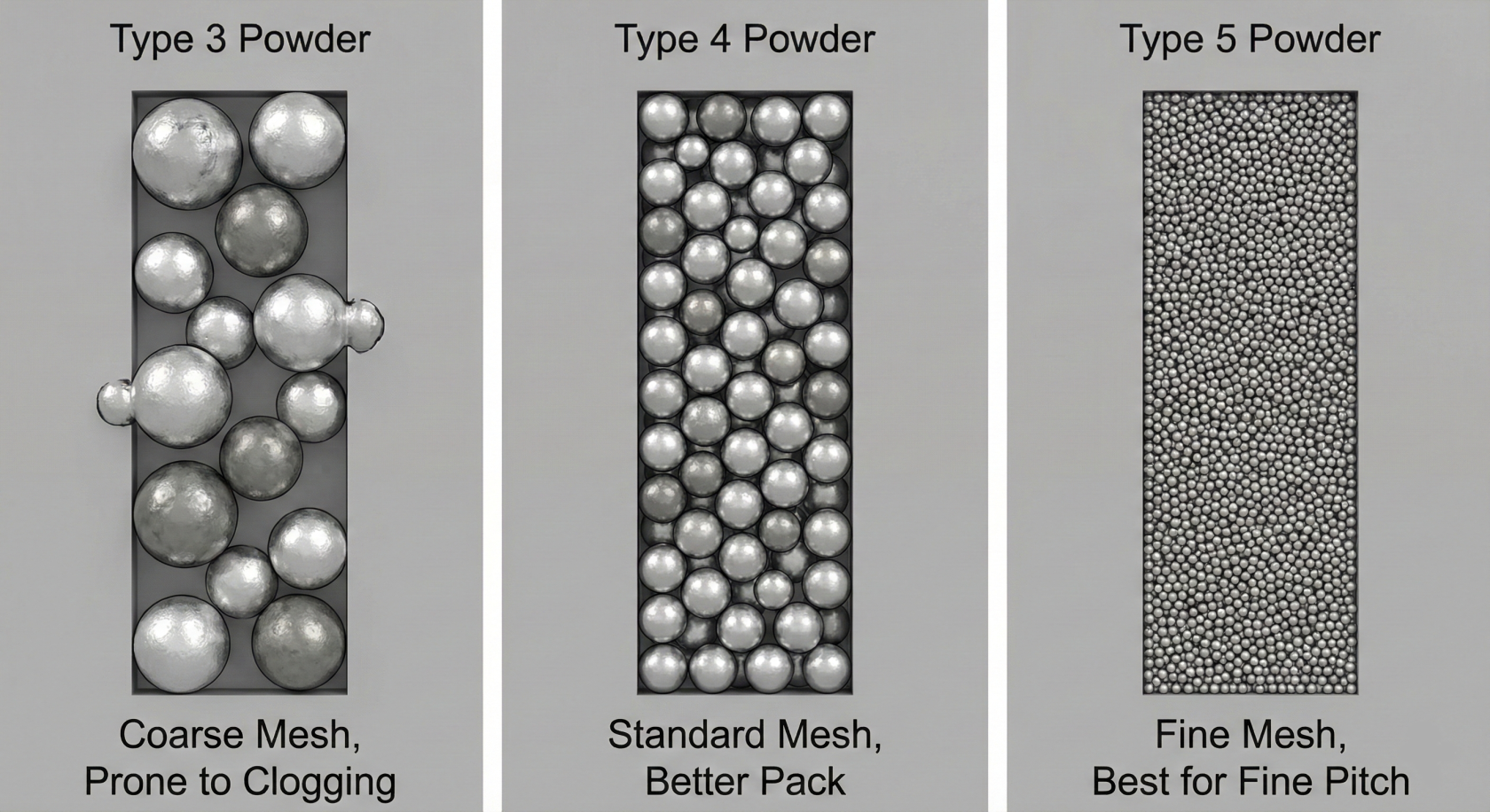

Smaller powder (e.g., Type 4/5) prints tighter apertures but oxidizes faster, narrows print/hold life, and can demand N₂ to keep wetting crisp. Larger powder (Type 3) is forgiving but taps out on very fine pitch. Match size to your aperture area/aspect ratios and component mix

Fast rules

- If your area ratios are marginal, move up a powder class or step the stencil locally.

- Tighter powder → tighten storage/handling and consider N₂ for reflow.

1.1.4 Alloy choice (what changes in reflow and life)

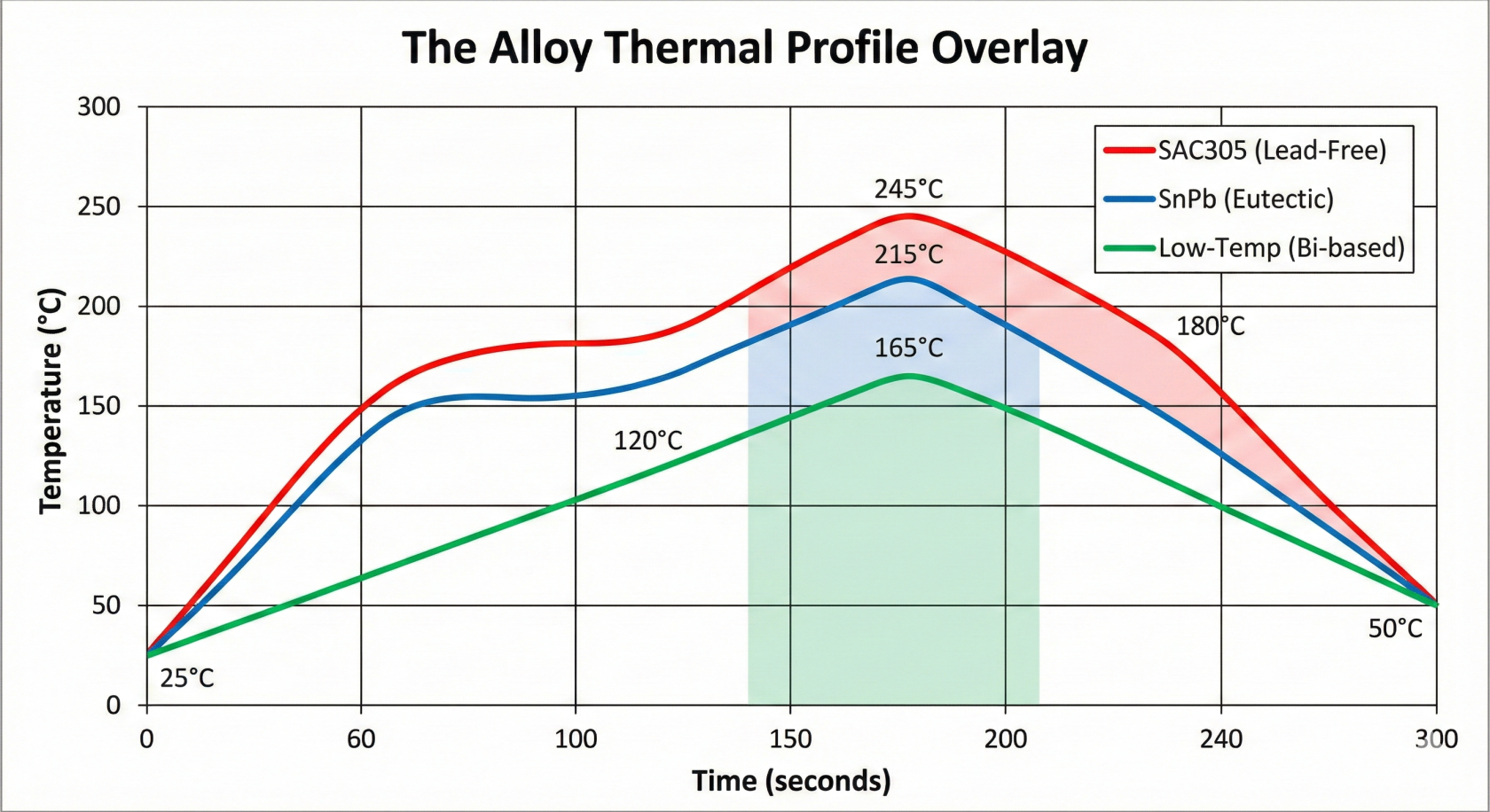

Different alloys want different profiles—don’t reuse SnPb curves for SAC or Bi mixes.

1.1.5 Map paste choices to your process window

Think window in three axes: print, reflow, cleanliness.

- Print axis: Powder size + rheology must hold volume/height/area steady across the shift. If you’re living at the edge, change powder/stencil—not operator heroics. (SPI & closed loop in 7.6.)

- Reflow axis: Alloy + flux decide TAL, peak, and need for N₂. SAC and low-temp pastes often benefit from nitrogen when pushing cosmetics/voiding. (9.2–9.3.)

- Cleanliness axis: No-clean saves time—if residues meet spec; water-soluble widens wetting but adds a whole cleaning process to control. (15.1–15.2.)

When windows feel narrow, run a small DOE: two powders × two atmospheres × two peak temps. Keep what moves your SPI→AXI Pareto the right way. (Window finding in 16.4.)

1.1.6 Starter picks (use, then tune with data)

- General lead-free builds: No-clean SAC with Type 3–4; air reflow unless BGAs/voiding push you to N₂.

- Fine-pitch BGA/QFN: No-clean SAC, Type 4 (or 5 if area ratios demand), consider N₂; pair with windowed apertures on thermal pads. (See 7.4.)

- Heat-sensitive boards/parts: Low-temp Bi-based paste; validate drop/mech and tune gentle profiles. (9.2/9.4)

- Legacy/service builds: SnPb where allowed; profile separately from SAC. (9.4)

1.1.7 Don’t forget the care & feeding

Great paste poorly handled is bad paste. Control storage, thawing, mixing, open time—we’ll set those rules in 6.2 and tie them to shelf life in Materials (17.4).

1.1.8 Release checklist (print this before you buy)

- Flux family chosen (no-clean vs water-soluble) and cleaning plan aligned.

- Powder size matched to smallest area/aspect ratios in your stencil set. (See 7.4.)

- Alloy picked with reflow profile plan (TAL/peak; air vs N₂). (9.2–9.4)

- Handling & shelf-life rules documented (storage, thaw/mix, open time). (7.2, 5.5)

- DOE plan ready if the early lots feel tight; tie reads to SPI/AOI/AXI dashboards. (7.6, 10.x, 16.4)