1.1 Paste Chemistry & Alloy Choice

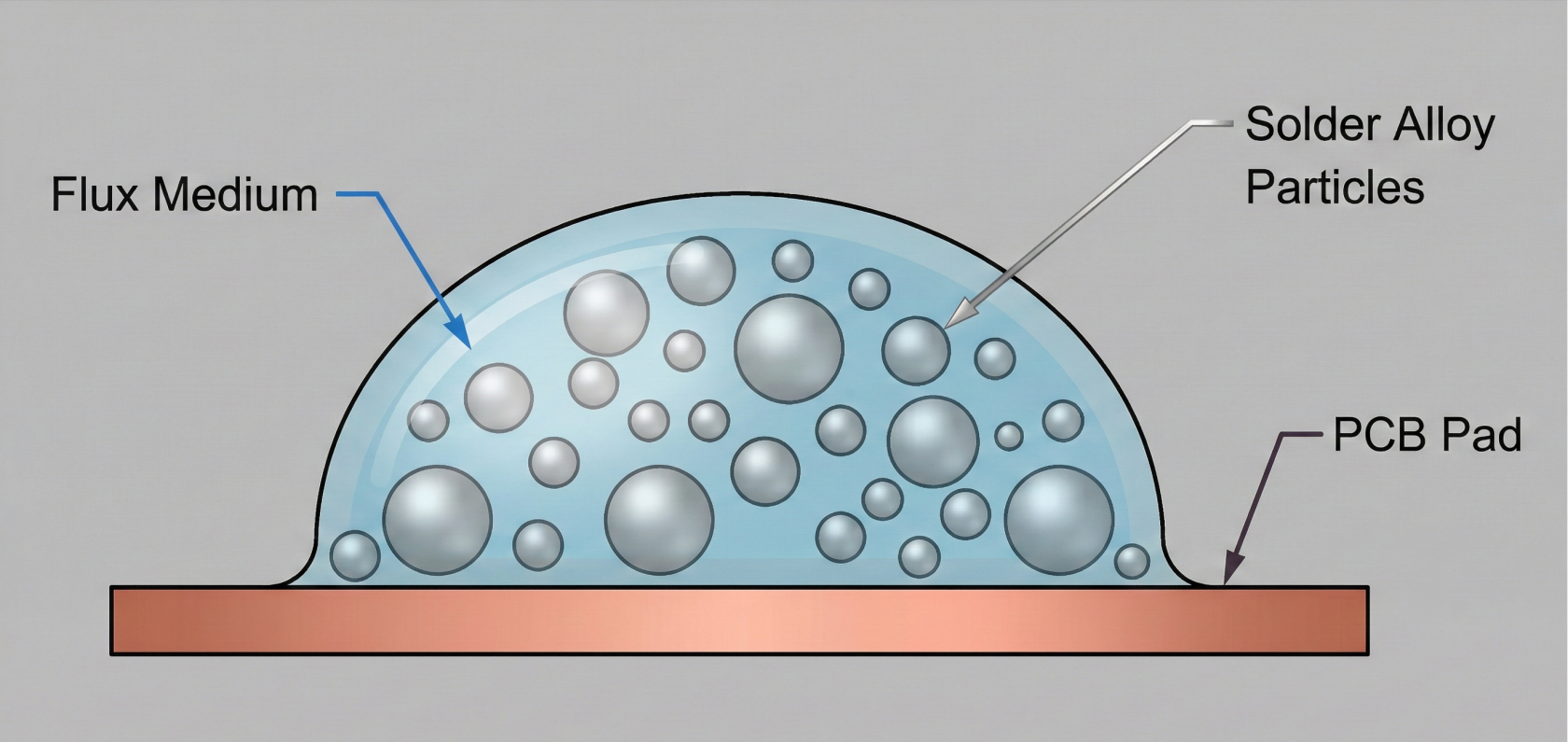

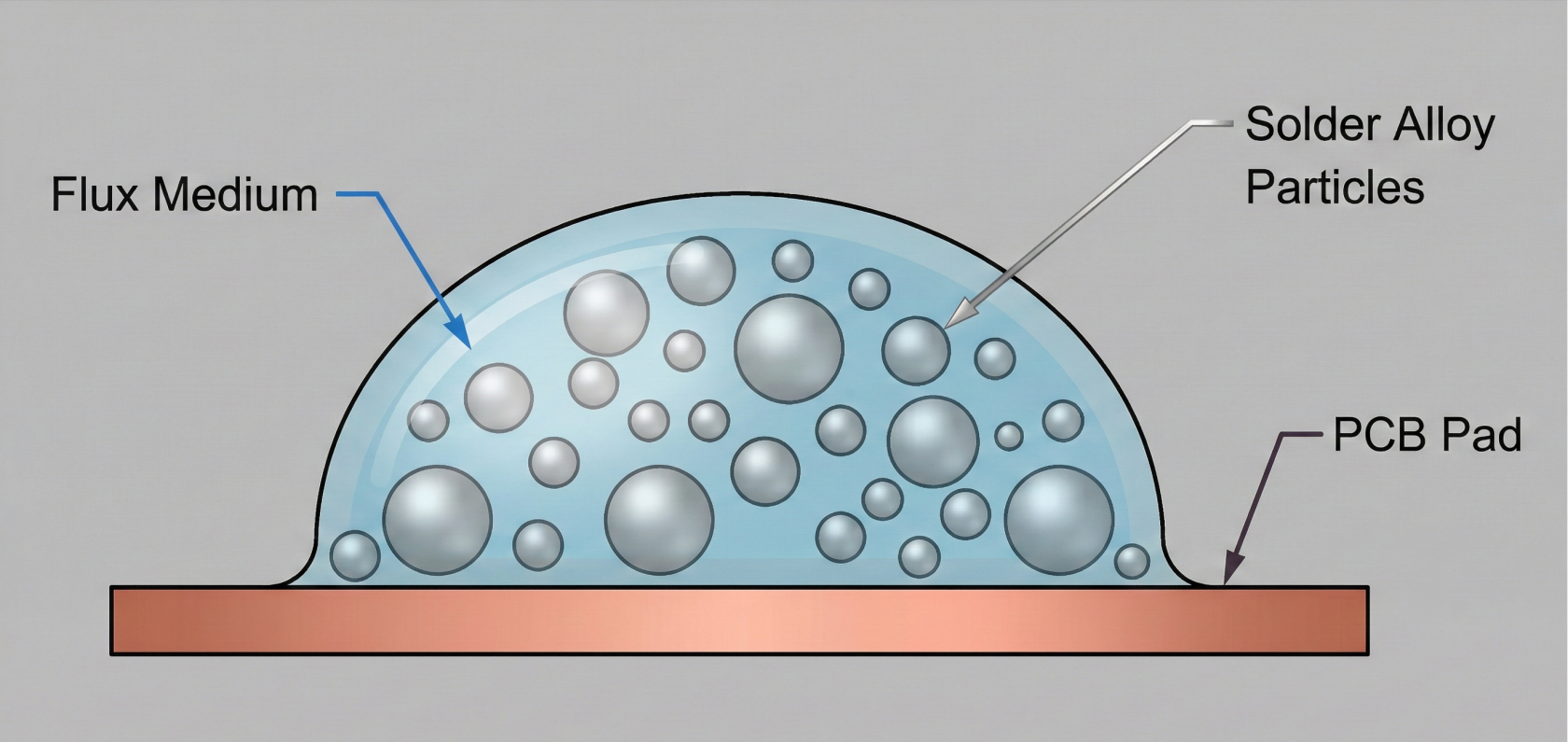

Solder paste sits atis the heartnervous system of surfaceSurface mountMount assembly,Technology and(SMT). itsIts chemistrychemical quietlymix dictates howevery smooth—orstep of the line—from how painful—productionclean willyour be.stencils stay to how reliable your joints are years down the road. The balance of flux,alloy, powder size,flux, and alloypowder determinessize everythingdefines fromyour stencilentire performanceprocess towindow. reflowGet stabilitythis right, and long-termproduction reliability.hums; Everyget tradeoff—betweenit print lifewrong, and fine-pitchyou’ll resolution,be betweenchasing wettingyield powerproblems and cleaning demands, between thermal limits and mechanical strength—defines the process window that keeps yields high and surprises low. Choosing wisely here sets the tone for the entire manufacturing line.forever.

1.1.1 What’s in a solderSolder pastePaste? (andThe whyThree you should care)Knobs)

AEvery paste is a suspension of three things, and you control all three:

alloy + flux + powder sizeAlloy:.AlloySetssetsthe meltingtemppoint (thermal profile) and the long-termbehavior;mechanicalfluxstrength/reliabilitydecidesof the joint.- Flux: The engine room. It cleans the metal, prevents oxidation during heating, dictates

printstencillife, wetting, residue/cleaninglife;,powderandsizedeterminesunlocksthe cleaning requirements. - Powder Size (Type): Unlocks your ability to print fine

aperturesfeatures.withoutIt’sslumpingtheorgatekeeperclogging. Every knob you twist here shows up inforprintingarea ratio andreflowvolume consistencylater—so pickonpurpose.small pads.

1.1.2 Flux systemsSystems: (no-cleanNo-Clean vsvs. water-soluble)Water-Soluble

This is the first major decision, impacting cost, cycle time, and risk.

Flux |

|

|

|

No- |

| Most |

|

Water- |

| Dense | High CapEx/OpEx |

Pro Tip: If inyou doubt,have startwetting no-clean,issues proveor residuesexcessive arevoids acceptable,on BGAs, WS paste is the technical solution. But remember, you’re trading a printing problem for a costly and keepcomplex water-solublecleaning process inyou yourmust backnow pocketvalidate forand stubborncontrol wetting/voiding cases.24/7.

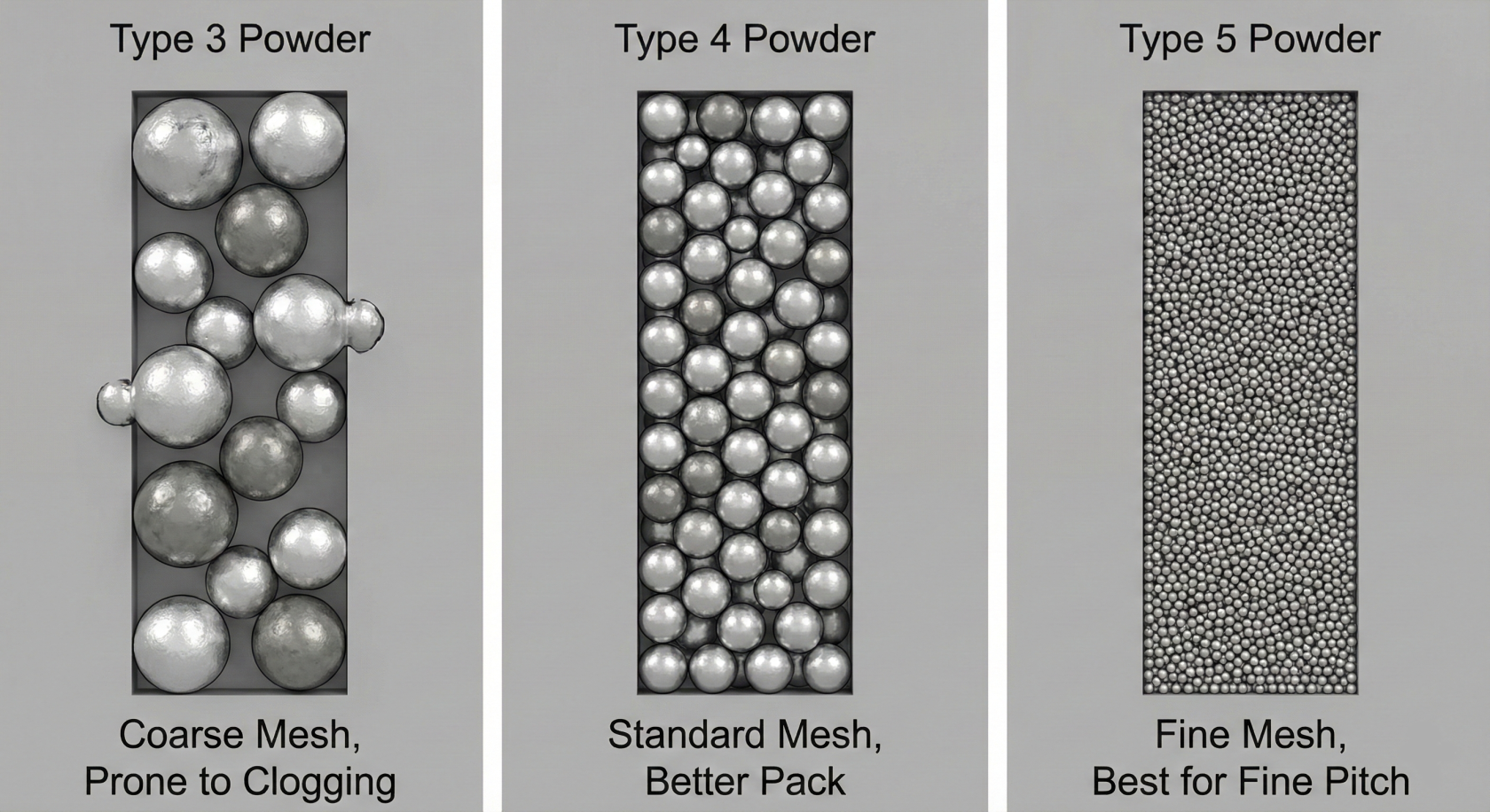

1.1.3 Powder sizeSize: Matching Aperture Ratios

The powder type must be smaller than the smallest stencil aperture opening to avoid clogging. This is where your Design for Manufacturing (whyDFM) meets reality.

Powder Type | Particle

| Use |

Type 3 (T3) |

| Default, forgiving |

Type 4 (T4) | 20 – 38 | Standard for Fine Pitch. Essential for 0.4 mm pitch QFNs and BGAs. A good balance between printability and handling. |

Type 5 (T5) | 15 – 25 | Ultra-Fine Pitch. Mandatory for 0.35 mm pitch components and the most marginal area ratios. |

Fast rulesRule:

- If your minimum

areaArearatiosRatioare(Aperturemarginal,Areamove/upApertureaWall Area) drops below 0.66, you must upgrade to the next smaller powderclasstype (e.g., T3or–stepT4the–stencilT5)locally. - to ensure consistent volume release and minimize clogging. Tighter powder

→ tightenmeansstorage/handlingtighter storage, handling, andconsiderprintN₂controlfor reflow.

.

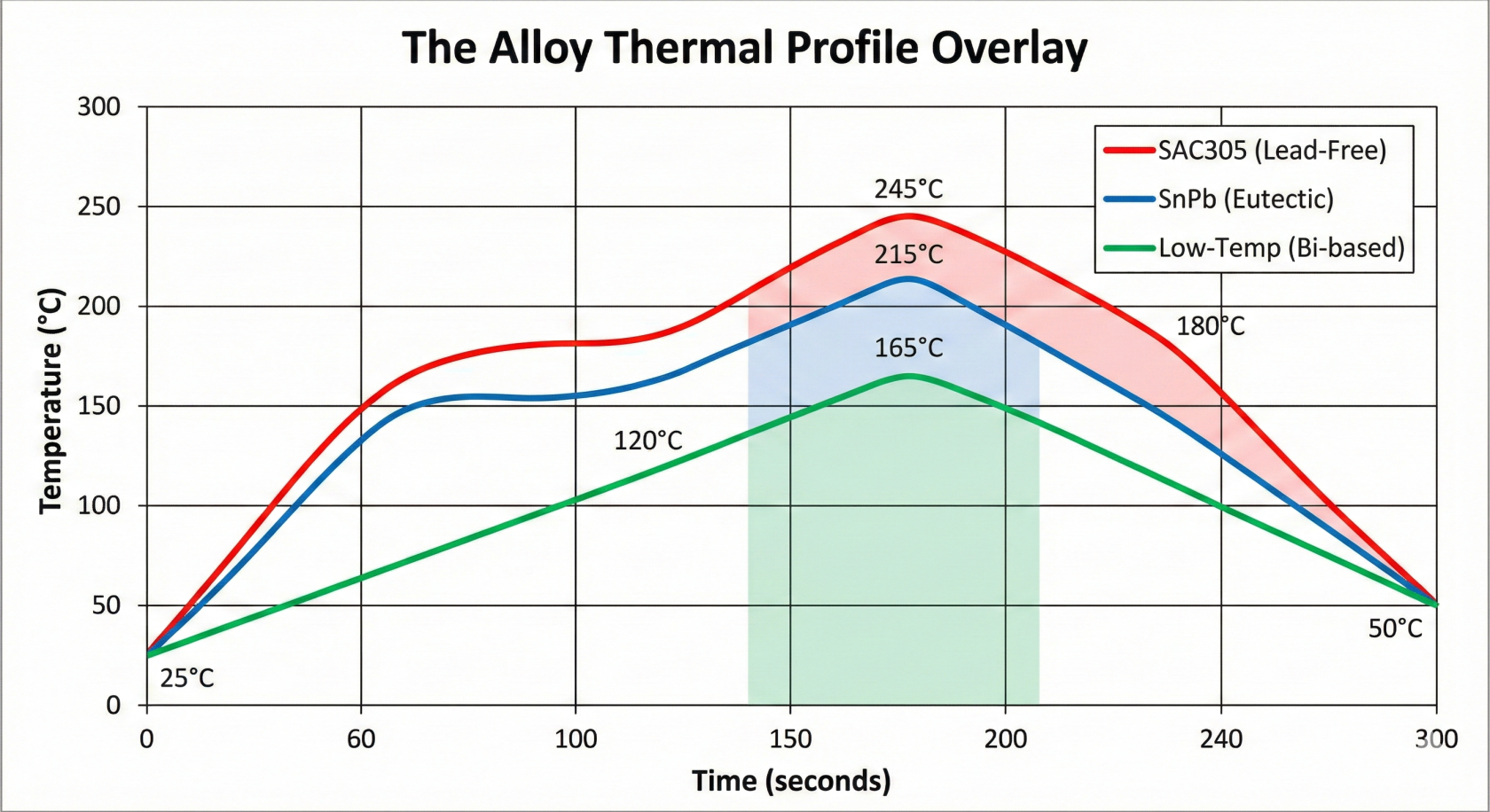

1.1.4 Alloy choiceChoice: (whatPerformance, changes in reflowProfile, and life)Reliability

Alloy choice sets the thermal profile and, more importantly, the long-term joint integrity.

Alloy |

| Process | Critical Reliability |

Sn63/Pb37 |

| Wide thermal | Not |

|

| Industry Standard Lead-Free. Needs | Superior thermal cycling fatigue resistance |

Low- |

| Great for heat-sensitive | Weaker mechanically. |

Manager Takeaway:Different alloysFor wanthigh-reliability, cycling applications, explore different profiles—don’t reuse SnPb curves fordoped SAC oralloys Bi(e.g., mixes.SAC-Q, SAC-I). These specialty pastes are engineered to resist micro-cracking and improve service life where temperature extremes are a factor.

1.1.5 MapMapping pasteYour choicesPaste to yourYour processProcess windowWindow

ThinkThe windowfinal inchoice must satisfy three axes:critical print,axes reflow, cleanliness.simultaneously:

- Print

axis:Axis (Rheology & Powder):PowderDoessizethe+paste’s rheologymust(its internal viscosity/flow) allow it to hold shape perfectly after the print stroke, or does itvolume/height/areaslumpsteadyandacrosscause bridging? Is theshift.tackIfstrongyou’reenoughlivingtoatholdthesmalledge,0201/0402changecomponentspowder/stencil—notthroughoperatorconveyorheroics.travel(SPIbefore& closed loop inreflow?7.6.(Check this with SPI/AOI data.) - Reflow

axis:Axis (Alloy & Flux):AlloyDo+the chosen alloy and fluxdecidechemistry allow you to consistently hit your target TAL, peak,andneedPeakfor N₂Temperature.SACwithoutandoxidizinglow-tempthepastesfluxoftenorbenefitstressingfromthenitrogencomponents?when(Checkpushingthiscosmetics/voiding.with(

When windowsthe feelwindow narrow,feels runtight, resist the urge to change the operator's settings. Change the paste, the stencil, or the atmosphere (add N2) instead. Run a small DOE:Design twoof powdersExperiments ×(DOE) twoto atmospheres × two peak temps. Keep what moves your SPI→AXI Paretofind the rightsweet way.spot, (Windowthen findinglock init 16.4.)

down.

1.1.6 Starter picks (use, then tune with data)

General lead-free builds:No-clean SACwithType 3–4; air reflow unless BGAs/voiding push you toN₂.Fine-pitch BGA/QFN:No-clean SAC, Type 4(or 5 if area ratios demand), considerN₂; pair withwindowed apertureson thermal pads. (See 7.4.)Heat-sensitive boards/parts:Low-temp Bi-basedpaste; validate drop/mech and tune gentle profiles. (9.2/9.4)Legacy/service builds:SnPbwhere allowed; profile separately from SAC. (9.4)

1.1.7 Don’t forget the care & feeding

Great paste poorly handled is bad paste. Control storage, thawing, mixing, open time—we’ll set those rules in 6.2 and tie them to shelf life in Materials (17.4).

1.1.8 Release checklistChecklist (printPrint thisThis beforeBefore youYou buy)Buy)

- Flux

familyFamily:chosenChosen (no-cleanvsvs. water-soluble);andcleaning process orcleaningresidueplanspecaligned.is documented. - Powder

sizeSize:matchedMatched to smallest aperturearea/aspectArearatiosRatioinonyourthestencil set.PCB (Seeusually7.4.)T4 for 0.5 mm, T5 for 0.35 mm). AlloyAlloy:pickedPickedwithbasedreflowon requiredprofile planreliability (TAL/peak;thermalaircycling)vsand confirmed against the availableN₂reflow profile).(9.2–9.4)limits.Handling & shelf-lifeHandling: Documented rulesdocumentedfor storage, thawing, mixing, and open time (storage,thethaw/mix,maximumopentimetime)allowed on the stencil).(7.2,5.5)DOE planValidation:readyPlanifintheplace to test early lotsfeel tight;and tiereadsresults directly to SPI/AOI/AXIdashboards.data(7.6,dashboards10.x,for16.4)process control.