1.1 The 5-Minute Mental Model

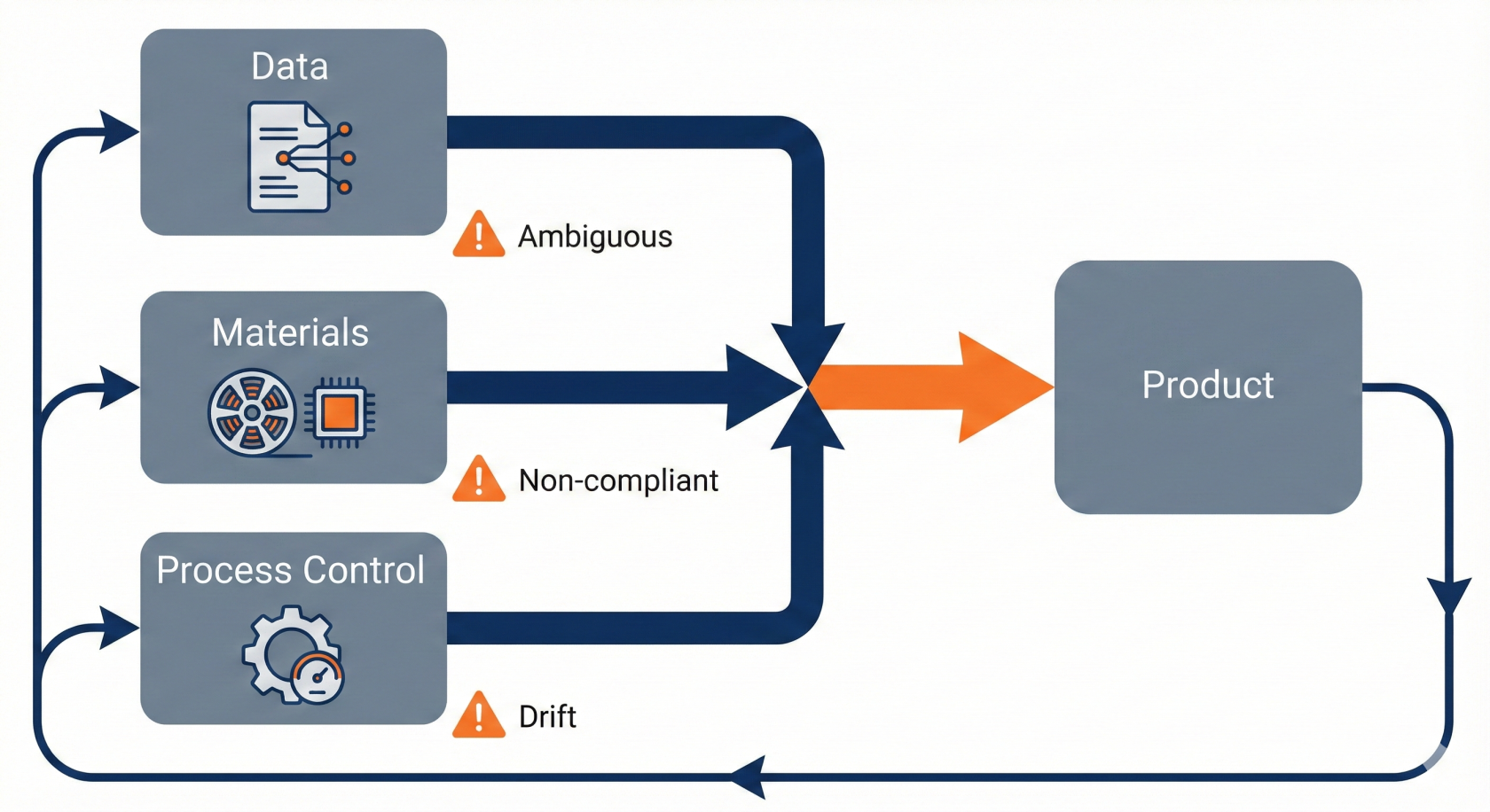

Electronics manufacturing operates on a rigid causal loop: Product = Data + Materials + Process Control. This is not a creative endeavor; it is a discipline of replication. An EMS (Electronics Manufacturing Services) provider exists to align these three inputs to produce a functional output. If the Data is ambiguous, the Material is non-compliant, or the Process drifts, the Product fails.

The EMS Equation

Manufacturing success depends on the synchronization of three variables. Treat them as a formula where a zero in any position results in zero output.

1. Data

Definition: The digital instruction set (Bill of Materials, Gerber files, Pick & Place coordinates).

Engineering Reality: Machines do not improvise. If the data specifies the wrong footprint, the machine places the component incorrectly.

- If Data is unverified → Then the error is replicated automatically across the entire batch.

2. Materials

Definition: The physical constituents (PCBs, Components, Solder Paste).

Engineering Reality: Physics governs performance. A capacitor with high Equivalent Series Resistance (ESR) generates heat regardless of assembly quality.

- If Material deviates from specification → Then the circuit reliability is compromised.

3. Process Control

Definition: The transformation actions (Printing, Placing, Reflowing, Testing).

Engineering Reality: Thermal and mechanical bonds require specific conditions. Solder paste requires a precise time-above-liquidus to form an intermetallic layer.

- If Process parameters drift → Then mechanical and electrical connections fail.

Defining Success

In the EMS industry, "success" is not subjective. It is defined by three specific, measurable outcomes.

Stable Quality

Quality is not "goodness"; it is conformity to a standard. A solder joint is either compliant with IPC (Institute for Printed Circuits) Class 2/3 standards, or it is a defect.

- Target: Zero deviation from the manufacturing file and IPC standards.

Predictable Lead Time

Time is a supply chain variable. Components have lead times ranging from 2 to 52 weeks. Success is the ability to predict the delivery date accurately, accounting for logistics and production throughput.

- Target: Delivery on the confirmed date, not earlier or later.

Controlled Cost

Cost control stems from efficiency and yield, not component substitution. Reducing scrap rates and optimizing line changeovers lowers the unit cost without introducing risk.

- Target: Minimizing waste (scrap, rework, downtime) to protect margins.

Handbook Vocabulary Standards

Precision prevents error. This handbook uses industry-standard acronyms to maintain brevity and accuracy.

- Rule: An acronym is expanded upon its first occurrence in a chapter.

- Usage: Subsequent mentions use the abbreviation.

- Example: New Product Introduction (NPI) is defined once; further references appear as NPI.

Pro-Tip: When reading technical documentation, never assume an acronym's meaning. "BOM" always means Bill of Materials in EMS, but context matters for terms like "NC" (Normally Closed vs. Not Connected).

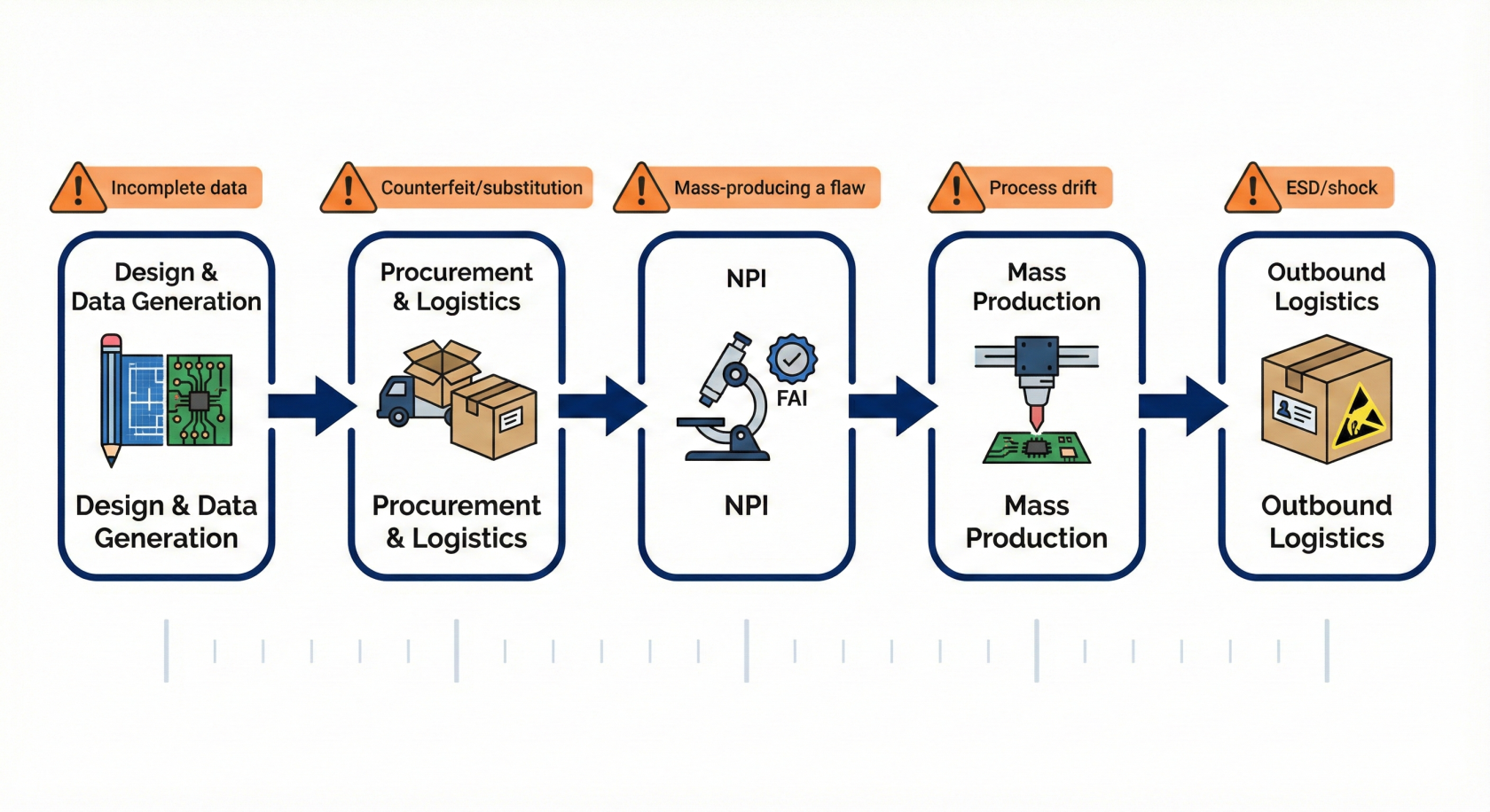

The Lifecycle Map: Idea to Shipment

Understanding the sequential flow of an electronics product is critical for identifying risk points.

1. Design & Data Generation

- Input: Schematics, Layout.

- Action: Generate Production Files (Gerber, BOM, CPL).

- Risk: Incomplete data stops production before it starts.

2. Procurement & Logistics

- Input: Approved BOM.

- Action: Source components from authorized distributors.

- Risk: Counterfeit parts or unauthorized substitutions.

3. New Product Introduction (NPI)

- Input: Kits and Data.

- Action: First Article Inspection (FAI), process validation.

- Risk: Mass producing a design flaw.

4. Mass Production

- Input: Validated Process.

- Action: SMT Assembly, Through-Hole, Reflow, Testing.

- Risk: Process drift causing latent defects.

5. Outbound Logistics

- Input: Finished Goods.

- Action: Packaging, Shipping.

- Risk: ESD damage or physical shock during transit.

Final Checklist

Variable | Metric | Critical Control |

Data | Accuracy | Validate BOM and Gerbers before release. |

Material | Traceability | Purchase only from authorized lines; require CoC (Certificate of Conformity). |

Process | Repeatability | Lock machine profiles; enforce statistical process control. |

Quality | Compliance | Inspect to IPC-A-610 standards (Class 2 or 3). |

Timeline | Predictability | Factor in component lead times before committing to a delivery date. |