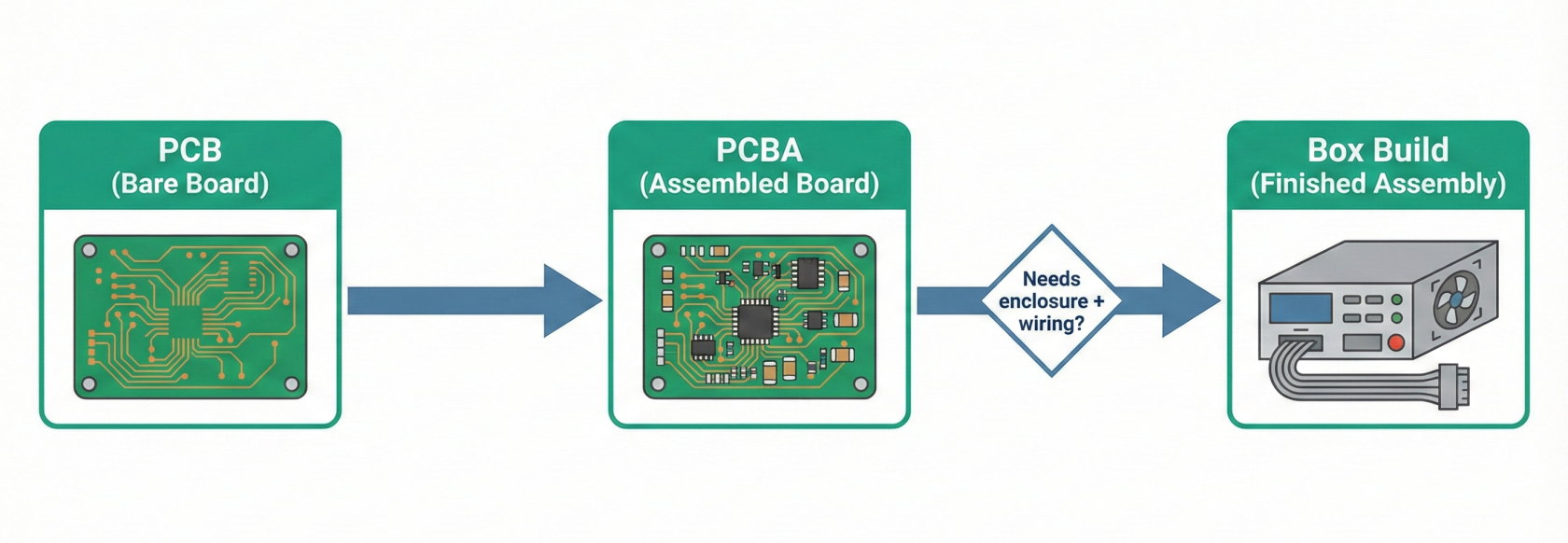

1.2 What Is Being Built: PCB vs PCBA vs Box Build

Precision in terminology is the first line of defense against manufacturing error. Using "PCB" when you mean "PCBA" confuses supply chains, misaligns quotes, and creates expensive delays. The manufacturing process is hierarchical: the bare board is a component of the assembly, and the assembly is a component of the final system. Understand the physical scope of the product to control the cost, schedule, and risk associated with each tier.

1. PCB (Printed Circuit Board)

Definition: The bare board. It is the mechanical chassis and electrical highway for the circuit, consisting of non-conductive substrate (FR4) and conductive copper traces. It contains no components.

The Engineering Reality

Treat the PCB as a complex custom mechanical part, not a commodity. It requires chemical etching, drilling, and plating. Once fabricated, it cannot be modified.

- If the PCB design has a layout error → Then every subsequent assembly will fail or require manual modification (jumper wires/cuts).

- Suppliers: Dedicated PCB Fabrication Houses (Fab Houses).

- Key Tooling: E-test fixtures, silkscreen screens.

- Typical Defects: Open circuits, shorts, delamination, warped boards.

2. PCBA (Printed Circuit Board Assembly)

Definition: The functional engine. This is the result of soldering electronic components onto the PCB. It transforms the passive board into an active electronic device.

The Engineering Reality

This stage introduces thermal dynamics and chemical reactions (flux activation). The goal is to create thousands of reliable intermetallic bonds simultaneously.

- If the thermal profile is incorrect → Then solder joints will be cold (brittle) or components will be heat-damaged.

- Suppliers: EMS Providers (Assembly Lines).

- Key Tooling: Solder Stencils, Pick & Place programs, Reflow ovens, ICT (In-Circuit Test) fixtures.

- Typical Defects: Solder bridges, tombstoning (components standing up), missing parts, reversed polarity.

Pro-Tip: Never judge a PCBA visually alone. A solder joint can look shiny and perfect but fail electrically due to internal voids or micro-cracks. Always rely on AOI (Automated Optical Inspection) and X-ray for BGA components.

3. Box Build (System Integration)

Definition: The finished product. This integrates the PCBA into an enclosure with human-machine interfaces (buttons, screens), wire harnesses, and final packaging. It is ready for the end-user.

The Engineering Reality

This moves from automated precision to manual mechanical assembly. Risk shifts from microscopic solder defects to macroscopic fit and function issues.

- If mechanical tolerances stack up poorly → Then the PCBA will not fit in the enclosure, or connectors will not align with the chassis ports.

- Suppliers: EMS Providers (System Assembly Departments) or dedicated Contract Manufacturers.

- Key Tooling: Injection molds, assembly jigs, functional test stands, screw robots.

- Typical Defects: Cosmetic scratches, pinched cables, loose fasteners, firmware version mismatch.

Cost and Complexity Scaling

Moving from PCB to Box Build exponentially increases the variables you must manage.

Cost Explosion

- PCB: Material + Fabrication. (Low Unit Cost)

- PCBA: PCB + Components (often 80% of BOM cost) + Assembly Labor/Machine Time.

- Box Build: PCBA + Mechanicals + Manual Labor + Logistics (shipping air inside boxes).

Lead Time Factors

- PCB: 1 – 3 weeks standard.

- PCBA: Defined by the "Long Lead Item." If one chip takes 40 weeks, the entire PCBA takes 40 weeks.

- Box Build: Includes tooling lead times (Steel molds for plastic cases can take 8 – 12 weeks).

Final Checklist

Level | Scope | Primary Risk | Critical Control |

PCB | Bare Board Only | Fabrication Defects | Electrical Test (E-Test) at Fab House. |

PCBA | Board + Components | Solder Joint Integrity | AOI and First Article Inspection (FAI). |

Box Build | Full Device | Mechanical Fit & Function | Functional Test (FCT) & Final QC. |

BOM | Bill of Materials | Obsolete Parts | Validate lifecycle status of all components before quoting. |