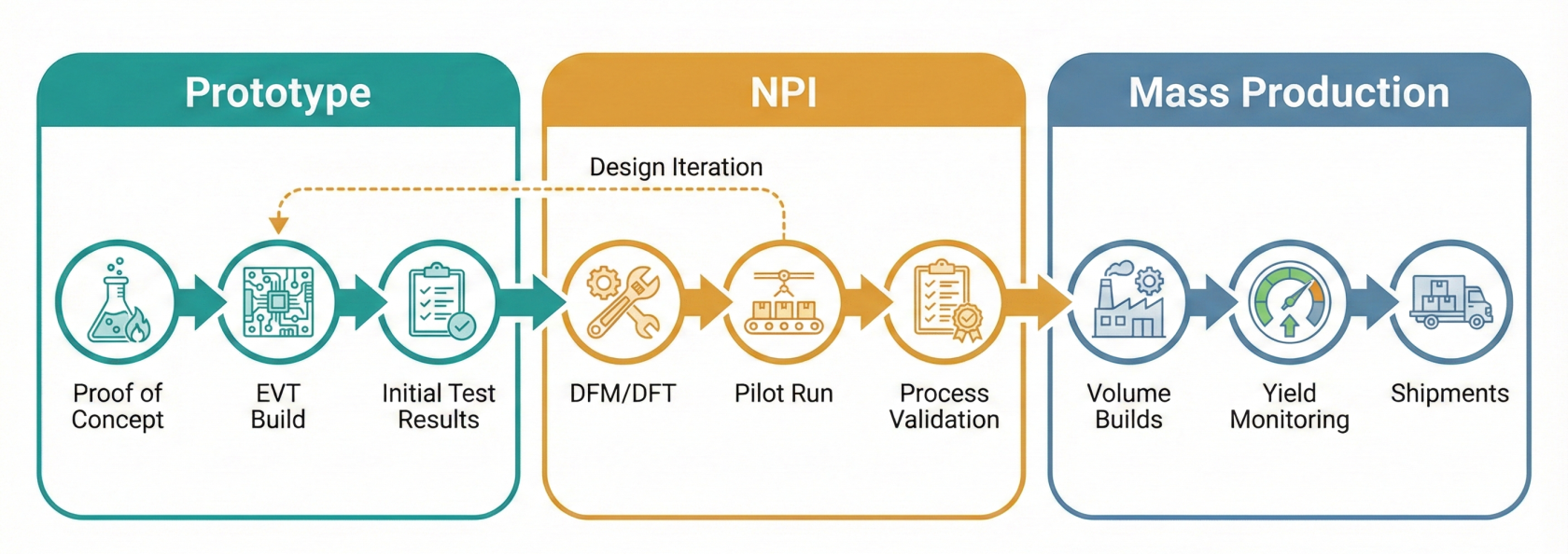

1.4 The End-to-End Lifecycle: Prototype → NPI → Mass Production

A common and expensive misconception is that Mass Production is simply a Prototype built at high speed. This is false. A prototype proves that a design works; Mass Production proves that a process works. The journey from a working unit on a lab bench to 10,000 units in shipping containers is a series of gates, not a slope. Each stage—Prototype, NPI, and Mass Production—has a distinct engineering objective, and skipping steps guarantees failure at scale.

1. Prototype (Proof of Concept)

Objective: Design Validation.

Quantity: 1 – 10 units.

This stage answers a single question: "Does the circuit perform the intended function?"

Speed is the priority. Components are often hand-soldered or placed by "rapid-turn" assembly lines that ignore efficiency in favor of agility.

The Engineering Reality

A successful prototype only proves the physics are sound. It does not prove the product can be manufactured. The tolerances used here are loose, and the labor is highly skilled technicians who manually correct design errors on the fly.

- If the prototype fails functional tests → Then redesign the schematic or layout immediately.

- Risk: False confidence. Just because one unit works does not mean 1,000 units will pass.

2. NPI (New Product Introduction)

Objective: Process Validation.

Quantity: 50 – 100 units (Pilot Run).

NPI is the bridge between theory and reality. It is the most critical phase in manufacturing. Here, the focus shifts from the product to the factory line. You are testing the tooling, the stencil apertures, the reflow profile, and the test fixtures.

The Engineering Reality

During NPI, the goal is to identify "DFM" (Design for Manufacturing) issues. If a connector is hard to plug in, or a capacitor is too close to the edge, it must be fixed now.

- If you skip NPI to save money → Then you will mass-produce defects, resulting in 100% scrap.

- If yield is below 98% in NPI → Then stop. Do not proceed to Mass Production until the root cause is solved.

Pro-Tip: Treat the NPI build as a stress test. Purposely use the full tolerance range of your components. If the device only works with "golden components" selected by hand, it is not ready for mass production.

3. Mass Production (MP)

Objective: Stability and Replication.

Quantity: 1,000 – 1,000,000+ units.

In MP, engineering creativity stops, and rigorous discipline begins. The goal is consistency. The process is "locked." Operators follow standard operating procedures (SOPs) blindly because the process has already been validated during NPI.

The Engineering Reality

Any change during MP is a risk. Even a "small" improvement to the firmware or a component substitution requires an Engineering Change Order (ECO) and often a partial re-validation of the line.

- If a process parameter drifts (e.g., oven temperature) → Then the line must shut down immediately until it is back within control limits.

- Risk: Supply chain disruption. At this volume, a shortage of a $0.01 resistor stops the shipment of a $500 product.

The Cost of Change (The 1-10-100 Rule)

Understanding when to catch an error is as important as fixing it. The cost to fix a defect increases by an order of magnitude at each step.

- Design Phase: Cost = $1 (Update the file).

- NPI Phase: Cost = $10 (Scrap the pilot boards, re-tool).

- Mass Production: Cost = $100+ (Recalling units from the field, brand damage).

Final Checklist

Stage | Primary Goal | Key Deliverable | The "Stop" Criteria |

Prototype | Does it work? | Functional Sample | Design fails to meet specs. |

NPI | Can we build it? | Validated Process & Tooling | Yield is unstable or low. |

MP | Consistency | On-Time Shipment | Unauthorized process changes. |

ECO | Change Control | Revision History | Never change MP without an ECO. |