1.3 Who Does What: OEM, EMS, ODM

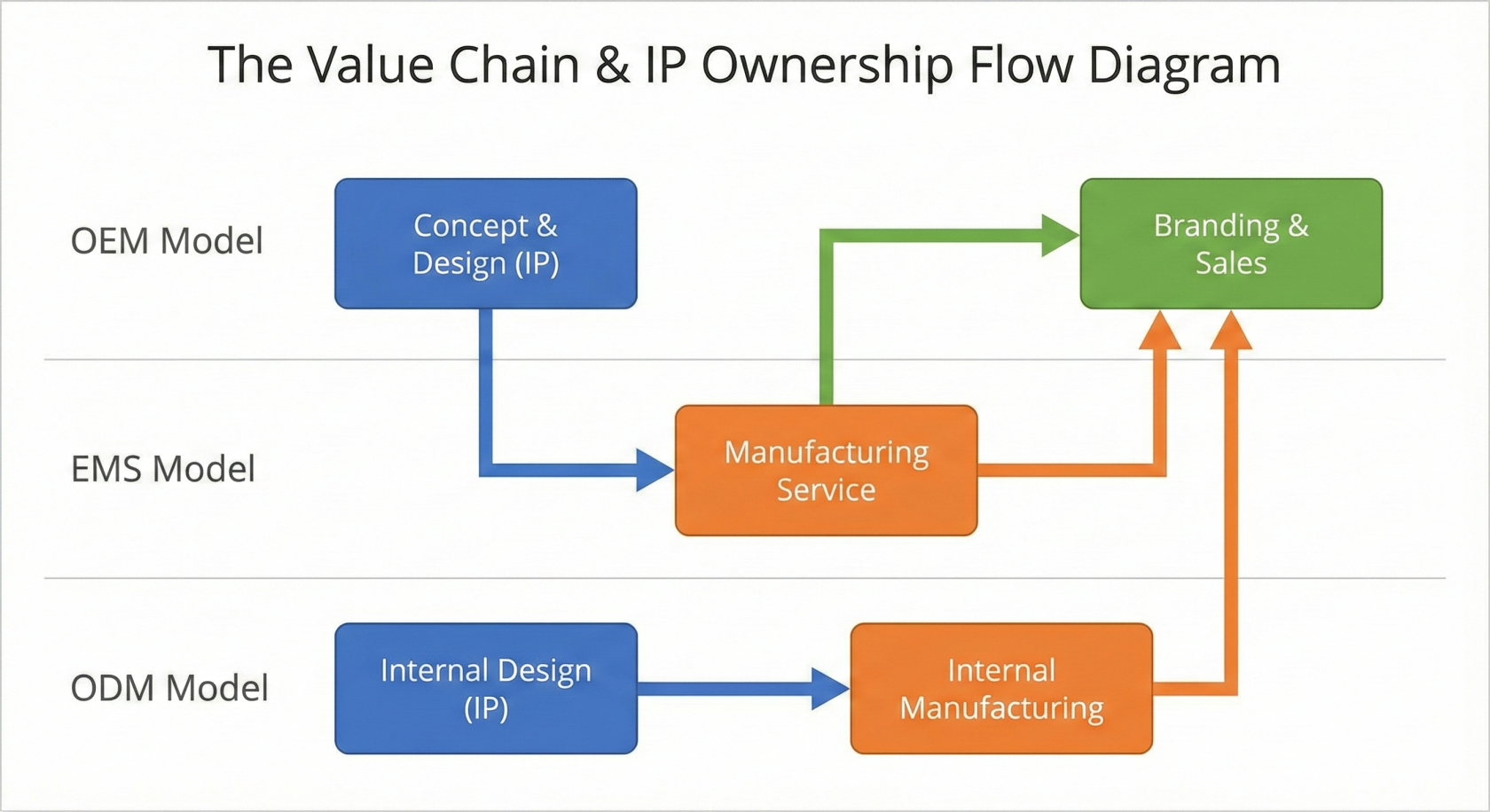

Manufacturing relationships are defined by one question: Who owns the Intellectual Property (IP)? Misunderstanding these acronyms is not just a vocabulary error; it is a legal and strategic failure. If you approach an EMS expecting them to design your product, you will wait indefinitely. If you approach an ODM expecting to own the design files, you will face a lawsuit. Clarity on roles defines who is responsible for the engineering data and who carries the liability for failure.

OEM (Original Equipment Manufacturer)

Role: The Architect and The Brand.

The OEM is the company that conceives the product, owns the brand, and sells to the end customer. They are responsible for the "what" and the "why."

The Engineering Reality

You own the design data (Gerbers, BOM, Source Code). You are responsible for the product's market success and regulatory compliance.

- If the product design is flawed → Then the OEM pays for the rework, not the factory.

- Primary Asset: Intellectual Property (IP).

- Risk: Market demand and design feasibility.

EMS (Electronics Manufacturing Services)

Role: The Builder.

The EMS provider sells manufacturing capacity, process expertise, and supply chain management. They do not design products; they execute the designs provided to them. They are the "hands" of the operation.

The Engineering Reality

The EMS ensures the process is correct. If they place a component exactly where the OEM told them to, but the location is wrong, the EMS has done their job correctly.

- If the machine places a part inaccurately → Then the EMS is liable.

- If the machine places a wrong part specified in the BOM → Then the OEM is liable.

- Primary Asset: Factories, SMT Lines, Process Control Standards.

- Risk: Capital equipment utilization and process yield.

Pro-Tip: An EMS is not a design consultancy. While they may offer "Design for Manufacturing" (DFM) feedback to lower costs, they will rarely fix a broken schematic. Do not send incomplete data hoping they will "figure it out."

ODM (Original Design Manufacturer)

Role: The Creator-for-Hire.

The ODM designs and manufactures products that are sold under another company's brand. They have a catalog of pre-designed "white label" products (e.g., standard Wi-Fi routers, phone chargers) that you can customize slightly.

The Engineering Reality

You are buying a finished shelf product, not developing a new invention. You typically do not own the design files. You cannot take the product to a different factory later because you do not own the IP.

- If you want to move production to a cheaper factory → Then you must start over, as the ODM retains all design rights.

- Primary Asset: A library of ready-to-sell product designs.

- Risk: Losing customers to competitors buying the exact same product.

The Liability Interface

Successful production requires a precise handover of information. The following table dictates what the manufacturing partner needs based on what the OEM controls.

If the OEM Owns... | The Manufacturer (EMS) Needs... | Because... |

The Schematic | A "Frozen" BOM | The EMS cannot buy parts for a design that is still changing. |

The PCB Layout | Gerber Files (RS-274X) & Pick-and-Place (XY) Data | Machines need coordinates, not pictures. |

The Firmware | Hex/Binary Files & Flashing Instructions | The factory operators do not compile code; they only load it. |

The Test Protocol | Functional Test Procedure | "Make sure it works" is not a valid instruction; pass/fail criteria must be binary. |

Final Checklist

Model | Design Ownership | Manufacturing Liability | Best For... |

OEM | OEM | OEM (Design) / EMS (Process) | Unique, innovative products where IP protection is critical. |

EMS | None | Process Defects Only | Companies with strong engineering teams who need scale. |

ODM | ODM | ODM (Product Function) | Generic commodities (chargers, basic peripherals) where speed beats uniqueness. |

Rule | N/A | N/A | Never combine models. Do not ask an EMS to design; do not ask an ODM for source files. |